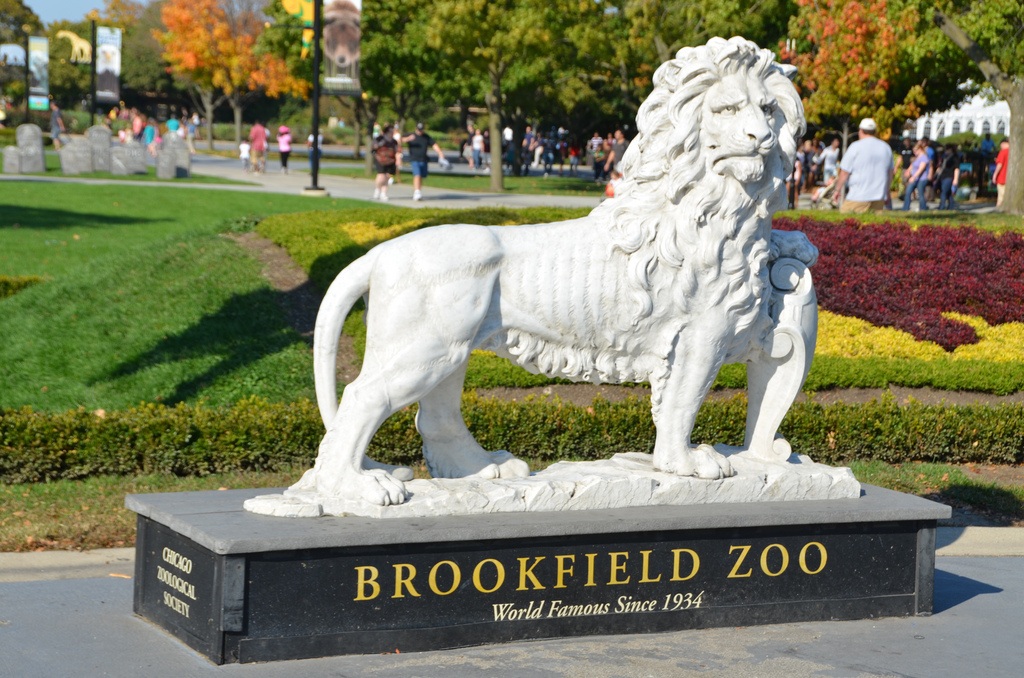

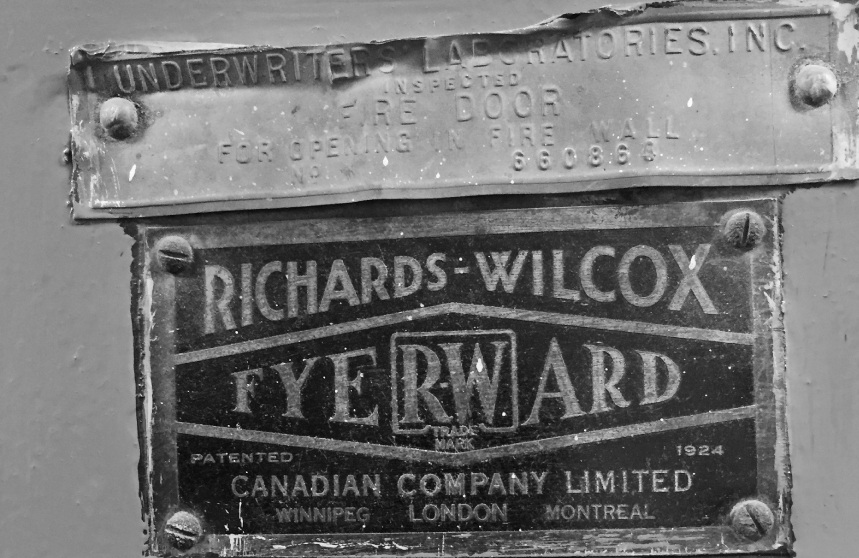

Richards-Wilcox products have coexisted with animals since 1880. It was then that the first hinges, tracks and other heavy duty components for barns, stables, corrals and other farm buildings were manufactured. Today, hundreds of agricultural facilities and zoos are equipped with Richards Wilcox hardware.

Clear Fold has extensive experience integrating this exceptionally safe and secure equipment for decades and is a select partner of Richards Wilcox. We invite you to learn more about our solutions and get in touch for a quote on your next project.

Safe and Sound

Maximum safety and security for animals and personnel.

The ultimate purpose of all Richards Wilcox hardware is to work in perfect conjunction with zoo doors, gates and barriers to provide maximum safety and security for animals and the personnel responsible for their care. Doors weighing as much as 5,000 lbs must open readily, close with ease, and firmly latch.

Richards Wilcox tracks, hangers, hinges and latches have the strength and precision to manage the brawniest doors. Zoo hardware must be able to withstand daily hosedowns in containment areas. Richards Wilcox hardware has a hot dipped galvanized finish applied to resist the most caustic washes. Hardware not finished in this manner could eventually fail and result in a breakdown of zoo safety standards. Moving a zebra from containment to exhibit or veterinary care must be done with confidence and caution. Crowding doors that nudge animals from area-to-area must slide forward and backward with precision and respond instantly to the direction of the handler.

Remote Access

Keeping your keepers and animals safe.

Ergonomic Vertical & Horizontal Lift

Designed with keeper and animal safety in mind, Richards-Wilcox Crank Operators provide zoos with an innovative standard for the remote operation of containment doors and gates. Available in styles for vertical lift or horizontal sliding doors, this ergonomic double-geared system is easy to operate and requires less muscle to operate even the heaviest doors. It eliminates oversized old style control wheels or the need for complicated gear-reduction typically used to aid in lifting heavy guillotine doors.

Heavy Duty Steel

- Galvanized and stainless steel options

- Resists corrosive, harsh environments

- Withstands daily cleaning and spraying

- Forged aluminum crank and plastic handle

Completely Enclosed Box

- Gears and operating mechanism are completely enclosed to eliminate injury to animals and keepers

- Enclosure protects parts from debris and corrosion

- Removable Front Cover for maintenance access

- Operators can be wall-mounted or mounted to caging

Automatic Failsafe Locking Mechanism

- Spring return locking mechanism

- Catches if accidentally released

- Can be padlocked

Ease of Use

Open a 3,000 pound Rhino door with 30 pounds of force.

Sliding Door Systems

Horizontal sliders used in caging should be paired with appropriately sized hangers and track to hold up to constant, daily use, operate smoothly, and move with little physical effort. Sliding door systems should have a low coefficient of friction. What this simply means is it should take little effort to move heavy doors.. Example: Take a 3,000 sliding door in a rhino enclosure. With track and hangers sized for this massive door there should only be 1% coefficient of friction. This translates to only 30 pounds of force required to move a very big door.

Swinging Door Systems

Correctly designed swinging zoo door systems should be easy for keepers to manage, requiring little force to move. Heavy duty hinges with ball or disc bearings should operate smoothly, while supporting the heaviest of entry doors, even those that weigh hundreds of pounds. The key is the right selection of hinge and the proper number of hinges sized to the door weight and height.