Clear Fold provides and integrates the finest Fiberglass Reinforced Plastic (FRP) doors in the marketplace – the unanimous choice of demanding architects, designers, owners and contractors worldwide. Our door and frame units include: Heavy Duty Door Series; Extreme Duty UL Fire Rated and Extreme Duty Hurricane/Windstorm Door Series; as well as Fixed Window Systems, Louvers, Thresholds, and Light Kits.

Every door is custom CAD designed and hand fabricated to your requirements and contain no ferrous metal or wood components in their construction that could lead to premature failure.

Heavy Duty

Reinforced Honeycomb Core

The Heavy Duty Door Series starts with a core that consists of a 3/8” triangular cell phenolic-impregnated kraft honeycomb surrounded by a rigid high-modulus, pultruded FRP tubular structural stile, rail and midrail sub-frame. At each of the sealed corner joints and hardware locations of the sub-frame, non-hygroscopic polymer blocking is inserted as reinforcement, providing the ultimate in strength for screw retention and compression resistance.

Unique Press-Mold Skins

The skins for the door begin with the application of an “in-mold” 25-30 mil gel coat. Then a chopped strand glass fiber mat is applied to form the connective tissue, followed by a muscular bi-axial glass fiber structural reinforcement layer that further strengthens the door skins.

Finally, the composite skins are simultaneously fused onto both faces and all edges of the door under pressure until cured — not only to the FRP sub-frame but to the entire honeycomb core—forming a bond that fully integrates all the components. Each door is factory finished with a specially formulated multi-component polyurethane industrial chemical coating for the semi-gloss color topcoat.

Lifetime Warranty

The Heavy Duty Door Series comes with a limited lifetime warranty and provides excellent service life and corrosion resistance for the most severe environments.

Extreme Duty – Fire Rated

Extreme Duty Fire Rated Doors have been successfully tested to both UL 10B (neutral pressure) and UL 10C/UBC 7-2 (positive pressure) test standards. These door and frame constructions blend the latest technologies in fire protection components with the attributes of fiberglass to provide the ultimate FRP UL fire rated barrier.

Seamless designs utilizing concealed category A intuemescents, in combination with factory pre-finishing available in 3 standard, 24 custom, or project specific color matched colors, provide aesthetically pleasing FRP openings to satisfy the most demanding architectural requirements.

Extreme Duty – Hurricane

Protection from wind speeds in excess of 300 mph.

Extreme Duty Hurricane doors meet or exceed the stringent requirements of the Florida Building Code (FBC), and the International Building Code (IBC) for hurricane rated openings. This product has been assigned Florida Product Approval Number FL7026 and is fabricated to Underwriters Laboratories manufacturing procedures ZHDL.R25222 and ZHCW.R25108. Up to 1½ hour UL fire ratings available for flush single swing and pair orientations.

These requirements include meeting specific design pressures up to and including +/- 150 pounds per square foot (225 psf over-pressure) and large missile impact resistance with no shutters required. These pressures can translate to protection from wind speeds in excess of 300 mph*.

* As determined by ASCE 7-98 “Minimum Design Loads for Buildings and Other Structures.” Topographic, importance and wind directional factors not included.

Pharmaceutical Duty

When cleanliness is a must.

Seamless with Non-Organic Materials

The Pharmaceutical Duty Door Series is seamless and manufactured with all non-organic materials. The core of the door consists of a 4mm cell polyproplene honeycomb surrounded by a rigid tubular FRP subframe. The skins for the door begin with the application of an “in-mold” 25-30 mil gel coat. Then a chopped strand glass fiber mat is applied to form the connective tissue, followed by a muscular bi-axial glass fiber structural reinforcement layer that further strengthens the door skins.

Unique Press-Mold Skins

The composite skins are simultaneously fused onto both faces and all edges of the door under pressure until cured — not only to the FRP subframe but to the entire polyproplene honeycomb core—forming a bond that fully integrates all the components. Each door is factory finished with a specially formulated multi-component polyurethane industrial chemical coating for the semi-gloss color topcoat.

Lifetime Warranty

The Pharmaceutical Duty Door Series comes with a limited lifetime warranty and provides excellent service life and corrosion resistance for interior pharmaceutical and medical environments where cleanliness is a must.

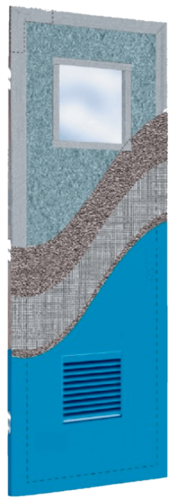

Available Accessories

Screwless Vision Lights Kits

Screwless Vision Light Systems have a unique snap-together installation design that gives you a smooth, clean look without the need to use exposed fasteners.

Louvers

Factory installed with optional bug/insect screen, louvers can be painted to match the color of the door or, when desired, with a different color.

Applied Moulding Applique

For a more decorative look, you can choose a standard 2, 4 or 6 panel look, or create your own unique design. Appliqués can be placed on one or both sides.

Thresholds

Thresholds can be painted any color desired and coated with a grip surface to meet anti-slip requirements.

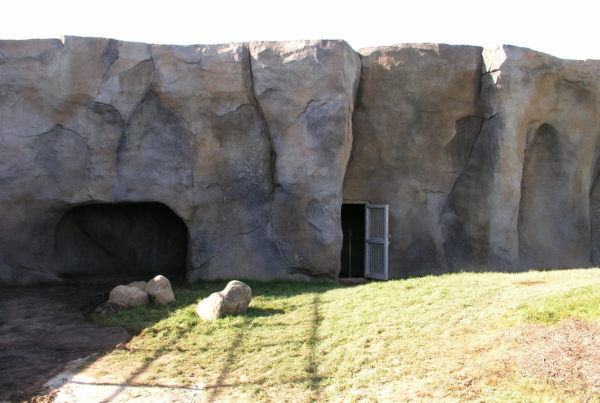

Application Spotlight

- Animal and Veterinary Services

- Chemical Manufacturing

- Educational

- Food Processing and Packaging

- Healthcare

- Marine and Offshore Structures

- Medical Research

- Oil Mining and Refining Systems

- Outdoor Recreations Structure

- Pharmaceutical Production

- Power Generation

- Pulp and Paper

- Transportation Systems

- Water and Wastewater

- Waterway Environments

- Zoos Aquariums and Themeparks